JIP Trial OverviewTrial demonstrations of the JIP inspection using VideoRay ROVs were conducted aboard the Ensco DS-1 vessel in dry dock in Cape Town, South Africa during the period of October 9th, though October 13th.

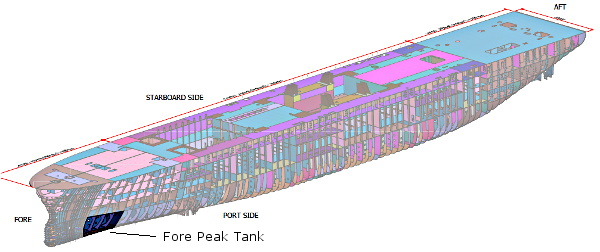

Additional information about the vessel is linked here for reference. Tank ConfigurationDemonstrations were conducted in Fore Peak Tank 101, located directly aft of the bow thrusters, frames 224-240. Frames in this section are spaced every 700 mm. The location of the tank is highlighted in this 3-D image.

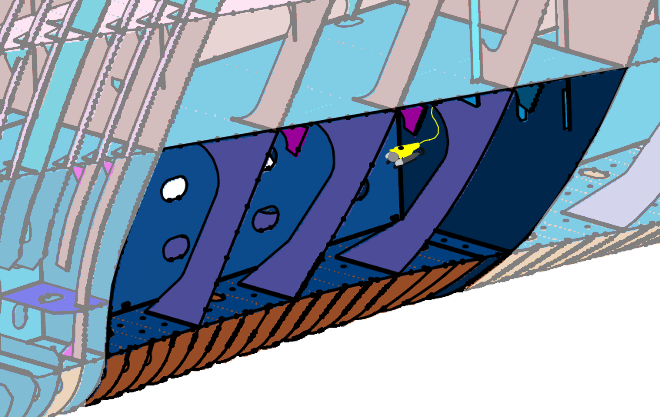

A close-up 3-D representation of the tank's construction is shown here.

Fore Peak Tank 101 is comprised of several compartments. There are two large compartments, one port and one starboard, separated by a central bulkhead. Within these two compartments, there are three (3) vertical structural ribs, which are spaced at every four (4) frames. Below these compartments are sixteen (16) smaller compartments also separated into port and starboard by a cental bulkhead (32 total compartments). Manholes in the vertical bulkheads, and floor of the larger compartments, allow access to every compartment. Some of the manholes in the floor have been blocked by bars prevent falls, but this also restricts access through these manholes. There are also several pipe structures within some of the compartments that restrict human access to these compartments or freedom of movement within them. Marking the Frame numbers in Fore Peak Tank 101 prior to flooding and inspection using the VideoRay ROV.

Representative manhole showing the confined space nature of the lower section of the Fore Peak Tank 101.

Valve structure that restricts human access to a bulkhead section between Frames 237 and 238 within the lower section of the tank. Several other bulkhead sections were also blocked by similar structural elements.

Demonstration EquipmentThe following equipment was utilized during this demonstration:

As you can see from this image, the system is small and can be transported in two cases. The control panel is installed in a Pelican case, model 1550 (52.4 x 42.8 x 20.6 cm; 20.62" x 16.87" x 8.12") and the ROV, tether and miscellaneous tools and accessories can fit in a Pelican case, model 1620 (62.6 x 49.2 x 35 cm; 24.64" x 19.39" x 13.78"). No component of the system weighs over 15 Kg (33 pounds). The system can be powered by any source capable of supplying 100-240 V AC, @ 50,60 Hz. DeploymentThe equipment is easy to transport, set up and deploy. The photo below shows the ROV being deployed in the tank through the access manhole.

Participants

Trial Demonstration Phases

The demonstration was originally scheduled for Tuesday through Thursday, October 9-11, but due to logistics issues, the first demonstration was not conducted until Thursday morning. The second demonstration was scheduled for Friday, but due to schedule issues, it was not conducted until Saturday morning. In order to capitalize on the down time, Tuesday was used to mark the tank, the tank was filled on Wednesday, and Friday was used to conduct a complete UT measurement survey of the hull plates in the tank using the VideoRay system. Trial Demonstration Procedures and ResultsThe demonstration procedures and results are described in more detail in the following sections, but it is important to note that all demonstrations were video recorded in their entirety, and several still images were captured during the demonstrations. Additional still images can be extracted from the video recording if desired. Note: The time required onboard the vessel for actual demonstration was much less than the indicated dates due to logistics issues and personal schedules of the observers. While the demonstration period spanned 5 days, the actual amount of demonstration time was on the order of approximately four hours, and a complete GVI and CVI test of the Fore Peak Tank 101 can be accomplished in about 1 hour. |

|

JIP Inspection Using VideoRay

Aboard Ensco DS-1

October 9-13, 2012

Aboard Ensco DS-1

October 9-13, 2012

JIP Trial Overview