Demonstration 1Date: October 11, 2012 In Attendance:

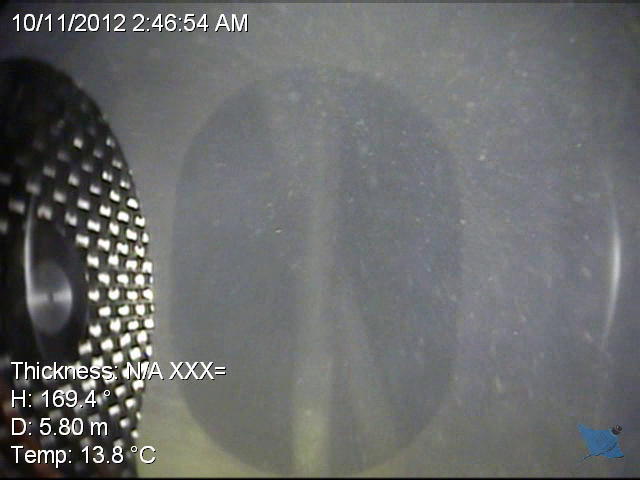

PreparationThe VideoRay ROV pre-dive checklist was completed and the UT gauge was calibrated and prepared for operation according to manufacturer's specifications. These tasks took less than 5 minutes and all systems passed the checks. The ABS surveyor was not present at time of calibration. Demonstration ExecutionThe demonstration started in the lower portions of Fore Peak Tank 101 in the areas that are accessed by manhole only. Corresponding Video Footage: Below are several sample images from the demonstration. Representative view of the lower section of Fore Peak Tank 101 showing bulkheads at Frames 238 and 239. The VideoRay can easily navigate throughout the confined spaces of the lower section of the tank.

Example of a video image of corrosion.

Example of a video image of an anode within the tank.

The following images show examples of some of the obstructions that were found in Fore Peak Tank 101 that prevent human access for entry and inspection of some of the compartments. These areas were easily accessible using the VideoRay ROV.

Close up of the valve structure from within a bulkhead section that was blocked by this valve, which prevented human access, but was easily accessible using the VideoRay.

Additional images of various obstructions making human access to the compartment dangerous, difficult or impossible.

The first portion of the demonstration confirmed:

The demonstration proceeded to the top open compartment of Fore Peak Tank 101. The second portion of the demonstration confirmed:

GapsThe ABS surveyor expressed two areas of concern:

VideoRay Comments on GapsIf a tank has excessive sludge it would have to be removed to be inspected exactly like a manned inspection. However there is an acceptable level of sludge that the videoray would still be able to record UT. The VideoRay did in fact record a UT measurements everywhere the Surveyor instructed. The VideoRay is routinely used in the open ocean, rivers, and has been used in internal structures while at sea. VideoRay acknowledges that there is a sea state limit; however the VideoRay will have no difficulty navigating a tank under normal operation circumstances. Several documented examples of using VideoRays in high sea states are available on VideoRay's website:. In these situations, the VideoRay proved successful, while other underwater systems could not even be deployed. Two example links are provided: |

|

JIP Inspection Using VideoRay

Aboard Ensco DS-1

October 9-13, 2012

Aboard Ensco DS-1

October 9-13, 2012

Trial Demonstration 1